Electrical devices are an integral part of our lives and we cannot imagine a day without them. However, this would not be possible without PCB boards. It is a green board that contains a lot of different electronic components. The substrate of the PCB board is composed of glass fibers, copper and other elements. The number of layers depends on the size of the production. It is a mandatory part of every electrical device and makes it work. And this applies to every category of electrical device. However, a lot of work needs to be done to make it work.

It refers to the unification of a large number of components and resistors, and the key factor is the PCB assembly process. It only takes one mistake to throw the whole process in vain. The consequence of bad installation is failure, lack of functionality, and even an accident can happen. You should know a little more about the steps in the PCB assembly process if you don’t want to make mistakes.

How long does it take to assemble a PCB?

There is no universal answer to this question. It all depends on the size, the number of components, the number of layers, as well as the complexity of the routing. The length of the process also depends on your experience and problem solving ability. For example, if you’re good with computers, you probably already know what software to get. You should run it and use it to set up simple circuit boards. The work will be finished in approximately 5 hours. In some situations, you will need less time. So your only obstacle is experience.

If you are a complete beginner, it will take you much more time, because you will have to learn to use electronic design automation software. To include creating a schematic diagram, adding components, etc. It takes people even a few years to master the basic knowledge, but there are software that are easier to learn and adapted to simpler projects.

In addition to software knowledge, you should also use definitions for components that. Of course, first check if you can even create the design you envisioned. There are design rules that you must not ignore.

Types of PCB materials

When it comes to the types of PCB board materials, we can divide them into three groups. The first group represents Rigid PCBs and these are used for devices that you see every day. The main characteristics of this material are hardness, strength and thickness. It also contains glass fibers that are fire resistant. They are mainly installed in power amplifiers, power switches, etc. Flexible printed circuit boards can withstand very high temperatures, bend easily and are used in wearable electronics. Finally, there is the metal core PCB. It is used in LEDs, laser diodes and similar items.

PCB layers

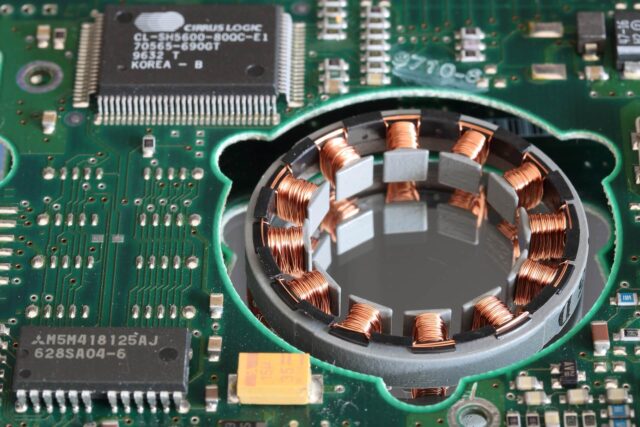

The PCB consists of a substrate or solid board. Components are glued to it. The copper foil is applied first, but it also comes at the end. A solder mask is also applied to the top and bottom of the PCB. In this way, water leakage to the PCB area and short circuit is prevented. With this mask, the possibility of unwanted soldering is eliminated. If you look closely, you will notice a mark on the PCB manufacturing. It contains vital information about the specimen of this PCB.

PCB assembly process

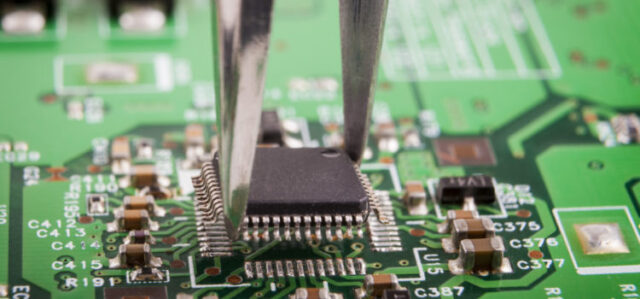

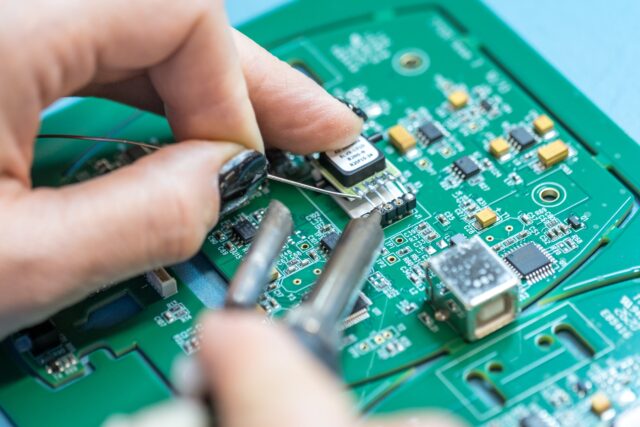

According to the Vinatronic, experienced PCB assembly and electronics manufacturer, traditional approach to board assembly involves using solder paste as the first step in the process. This is not always the case, as with THT. Next, the components are placed on the board. Placement of components can be done manually or by machine. In the traditional approach, components are entered manually. The procedure requires extreme precision. Of course, automatic placement is a much faster and more accurate option. If we continue with the traditional approach, the next step would be reflow. In this case, the solder turns into a liquid state and then returns to a solid state.

The components are constantly moving through the oven, which maintains the temperature and prevents premature cooling. After that, the board is moved to a cooler and the solder is cooled. On the other hand, THT does not require resoldering. Instead, the board is inspected and corrected, followed by component placement. The CMT process requires working in the moment. This means that the board is placed in the oven, the solder paste melts and goes into the cooler. There, the temperature gradually decreases, the solder turns into a solid state and the components are fixed in place. The next step is to inspect the board, soldering and components. During the manual process, parts need to be inserted into the hole. Finally, the last inspection and cleaning is done. This will remove all residue and excess solder.

Which PCB assembly process should I choose?

There is no one-size-fits-all solution. So you should consider your needs, budget and goals. For example, if you only want one prototype board, the THT method may be the best choice. However, if you want something completely different, we’re sure you don’t want THT. Whether you want many products or just one, find a company that is reliable and recognizes your needs. To be sure, you can schedule a consultation or find information online. Research their services, costs and business policies.

Conclusion:

PCB board is present in all industries such as automotive, consumer electronics, aerospace and many others. That’s why it’s important to know everything about design, technology trends and other important things related to PCBs. We hope that our text was useful to you and that you got an answer to your question.

Don’t forget that every situation is different, which means there are multiple solutions. Not every solution may be right for your project, but don’t stop at the first hurdle. For all other questions, please contact the experts who will help you better understand the PCB manufacturing processes. They can even guide you step by step and that is the best choice if you are not sure in your skills and knowledge at the moment.